INNOVATION IN POULTRY TECHNOLOGY AND AUTOMATION

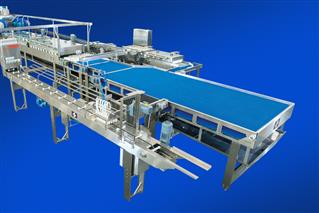

Yamasa LCHS-108.000 with Accumulator 108.000 eggs/hour Grader with washer

Width

0.00 m

Height

0.00 m

Length

0.00 m

Capacity

108.000 ovos/hora

HIGH CAPACITY AND EASY AMPLIFICATION

The Yamasa LCHS-108.000 with Egg Accumulator is designed for use in the USA. It is produced in a module system, assembled in line, which allows the expansion of the equipment, adapting it to different egg room plants, according to the needs of the farm.

It is suitable for large egg rooms that receive eggs from the automatic conveyor belt directly from the aviary and, at the same time, also from the egg room. It has high sorting ability. The grading of eggs is This is done through electronic weighing, with high-precision load cells. It has the capacity to classify 108,000 eggs/hour, with 12 egg outlets, being automatic packers for cases or trays, and manual outlets for jumbo, industrial or microcracked eggs, directed on a special conveyor belt in the models that have the crack detector. It has a washer, egg dryer and candling.Accessories included

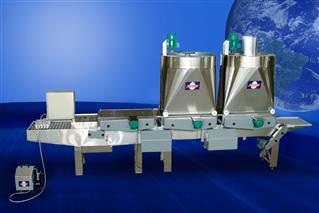

Model ALY-1800 Egg aligner

ALY-1800 Egg Guiding Egg aligner

egg receiving table

Accessory that receives the eggs directly from the aviary mat.

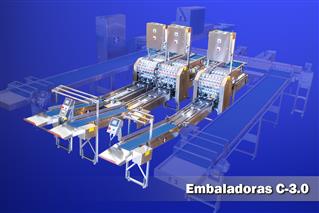

Model C-3.0 packers

Automatic, the C-3.0 packaging machine is versatile and adaptable to all models and sizes of trays and cases.

Candling Model OV-6

This accessory allows you to detect defects in the shell, broken eggs, cracks and internal abnormalities.

Yamasa washer and dryer

The Yamasa washer has brushes designed for gentle cleaning that won`t damage the eggs.