INNOVATION IN POULTRY TECHNOLOGY AND AUTOMATION

News

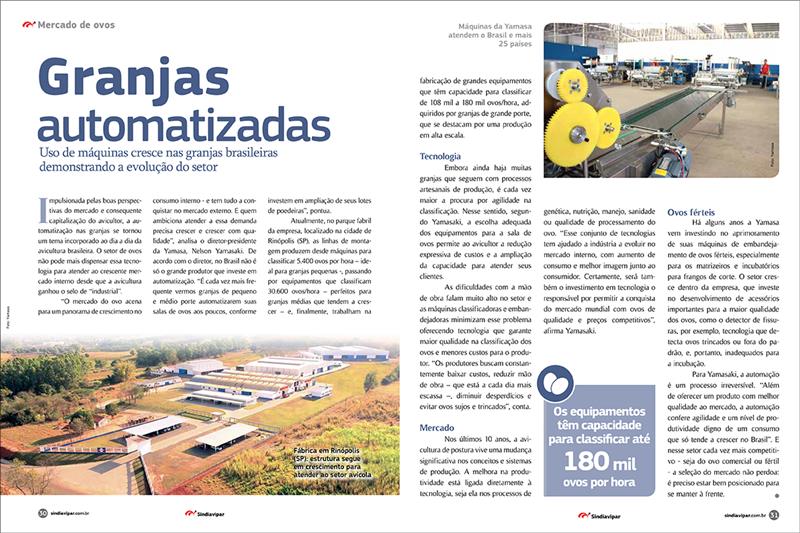

Yamasa is featured in a report on farm automation

Article published in the 63rd edition of Revista do Sindiavipar (PR) highlights the company`s trajectory and its dedication to the fertile eggs sector, with the YHD Line.

The egg market and the search for automation of farms is a must. This is the subject of the article in Revista do Sindiavipiar, issue 63, which highlights Yamasa and his dedication to the egg sector. In the report, which occupies pages 30 and 31 of the publication, businessman Nelson Yamasaki, president of Yamasa, highlights the work of the company that was born a few years ago. 52 years old and remains prestigious in Brazil and in 25 other countries around the world.

Sindiavipar, the entity that publishes the magazine, is responsible for publishing the magazine. representative of the poultry product industries of the State of Paraná, a Brazilian state, by the way, which is the largest chicken producer and exporter in the country. It is one of the bases of Paraná`s economy and has an important partner in Yamasa offering its experience and quality products in the packing of fertile eggs.

Check out the article in its entirety below, and also read it, in PDF, at the link Sindiavipar Magazine Issue 63.

AUTOMATED FARMS:

MACHINE USE IS GROWING ON BRAZILIAN FARMS, DEMONSTRATING THE EVOLUTION OF THE SECTOR

Driven by the good prospects of the market and the consequent capitalization of the poultry farmer, automation in farms has become a theme incorporated into the daily life of Brazilian poultry. The egg sector can no longer dispense with this technology to meet the growing domestic market since poultry farming gained the “industrial” seal.

“The egg market beckons to a panorama of growth in domestic consumption - and has everything to conquer in the foreign market. And those who aspire to meet this demand need to grow and grow with quality”, analyzes Yamasa`s CEO, Nelson Yamasaki. According to the director, in Brazil it’s not possible. only the big producer that invests in automation. “ It is increasingly common to see small and medium-sized farms automating their egg rooms little by little, as they invest in expanding their batches of laying hens”, he points out.

Currently, in the company`s industrial park, located in the city of Rinópolis (SP), the assembly lines produce from machines to classify 5,400 eggs per hour – ideal for small farms - including equipment that classifies 30,600 eggs/hour – perfect for medium farms that tend to grow – and, finally, they work in the manufacture of large equipment that has the capacity to classify from 108,000 to 180,000 eggs/hour, acquired by large farms, which stand out for their high production. scale.

Technology

There is an ever-increasing demand for agility in sorting. In this sense, according to Yamasaki, the proper choice of equipment for the egg room allows poultry farmers to significantly reduce costs and expand their capacity to serve their customers.Difficulties with labor speak volumes in the sector and the sorting and packing machines minimize this problem by offering technology that guarantees higher quality in the classification of eggs and lower costs for the producer. “Producers are constantly looking to lower costs, reduce labor – every day more scarce –, reduce waste and avoid dirty and cracked eggs”, he says.

Market

In the last 10 years, poultry farming has experienced a significant change in production concepts and systems. The improvement in productivity is at hand. connected directly to the; technology, whether in genetics, nutrition, handling, health or egg processing quality. “This set of technologies has helped the industry to evolve in the domestic market, with increased consumption and better image with the consumer. It is also the investment in technology that is responsible for allowing the conquest of the world market with quality eggs and competitive prices”, says Yamasaki.

Fertile eggs

There is; For a few years Yamasa has been investing in the improvement of its hatching egg packing machines, especially for hatcheries and hatcheries for broiler chickens. The sector grows within the company, which invests in the development of important accessories for the highest quality of eggs, such as the crack detector, for example, technology that detects cracked or non-standard eggs, and, therefore unsuitable for incubation.

For Yamasaki, automation is key. It is an irreversible process. “In addition to offering a product with better quality to the market, automation provides agility and a level of productivity worthy of a consumption that is only possible. tends to grow in Brazil”. And in this increasingly competitive sector - be it commercial or fertile eggs - market selection is unforgiving: it`s difficult. you need to be well positioned to keep up; front.